This web page was created programmatically, to learn the article in its unique location you possibly can go to the hyperlink bellow:

https://scitechdaily.com/how-copper-smelters-accidentally-sparked-the-birth-of-the-iron-age/

and if you wish to take away this text from our web site please contact us

Copper smelters as soon as used iron oxide to refine copper, unintentionally advancing the trail towards iron metallurgy.

Research carried out at Cranfield University offers new perception into the shift from the Bronze Age to the Iron Age, suggesting that copper smelters experimenting with iron-rich rocks could have unintentionally paved the way in which for the invention of iron.

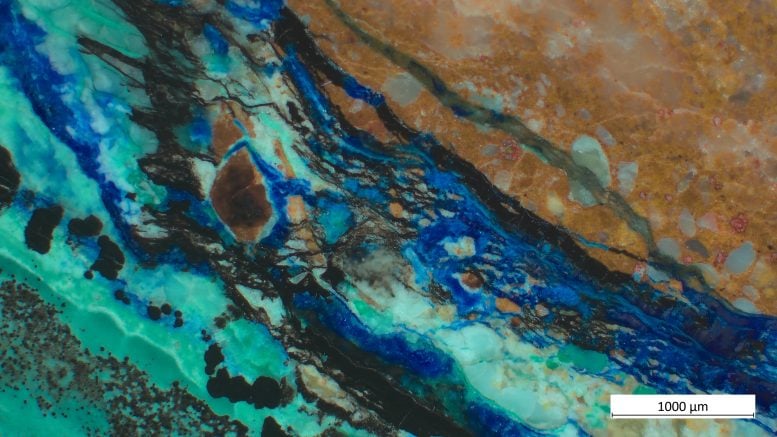

The research revisited metallurgical stays from Kvemo Bolnisi, a 3000-year-old smelting web site in southern Georgia. When the positioning was first examined within the Nineteen Fifties, archaeologists uncovered heaps of hematite (an iron oxide mineral) and slag (the by-product of metalworking). Because of the iron oxides, the unique workforce concluded that the workshop had been used for early iron manufacturing.

Copper smelting with iron oxides

Recent evaluation challenges that interpretation. Instead of manufacturing iron, the smelters at Kvemo Bolnisi have been working copper and added iron oxide as a flux, a fabric that improves effectivity by boosting the quantity of copper extracted.

This discovering helps the long-standing concept that the origins of iron metallurgy could also be traced to copper staff. Evidence now exhibits that historical metallurgists intentionally launched iron-bearing supplies into their furnaces, marking a vital stage within the eventual growth of iron smelting.

From uncommon iron to widespread use

Although the Iron Age represents the beginning of large-scale ironworking, the metallic itself was already recognized in earlier intervals. Iron artifacts from the Bronze Age embrace notable examples similar to Tutankhamun’s dagger, which featured a gold and rock crystal hilt with an iron blade. However, these early objects have been crafted from metallic iron that had fallen to Earth in meteorites relatively than extracted from ore. Because of its shortage, iron was at the moment thought-about much more valuable than gold.

The growth of extractive iron metallurgy modified all this. Iron is likely one of the most plentiful parts on Earth, despite the fact that naturally occurring iron metallic could be very uncommon. The means to extract iron from iron ore and work it into helpful supplies similar to instruments or weapons is likely one of the defining technological transformations in human historical past. The transition into the Iron Age was removed from instantaneous, but it surely gave rise to the iron-wielding armies of Assyria and Rome and later the railroads and steel-frame buildings of the Industrial Revolution.

Insights from Kvemo Bolnisi

Dr. Nathaniel Erb-Satullo, Visiting Fellow in Archaeological Science at Cranfield University, stated: “Iron is the world’s quintessential industrial metallic, however the lack of written information, iron’s tendency to rust, and a scarcity of analysis on iron manufacturing websites have made the seek for its origins difficult.

“That’s what makes this web site at Kvemo Bolnisi so thrilling. It’s proof of intentional use of iron within the copper smelting course of. That exhibits that these metalworkers understood iron oxide – the geological compounds that will ultimately be used as ore for iron smelting – as a separate materials and experimented with its properties throughout the furnace. Its use right here means that this type of experimentation by copper-workers was essential to the event of iron metallurgy.

“There’s a beautiful symmetry in this kind of research, in that we can use the techniques of modern geology and materials science to get into the minds of ancient materials scientists. And we can do all this through the analysis of slag—a mundane waste material that looks like lumps of funny-looking rock.”

Reference: “Iron in copper metallurgy at the dawn of the Iron Age: Insights on iron invention from a mining and smelting site in the Caucasus” by Nathaniel L. Erb-Satullo and Bobbi W. Klymchuk, 26 September 2025, Journal of Archaeological Science.

DOI: 10.1016/j.jas.2025.106338

The analysis was supported by grants from the British Institute of Ankara, the Gerda Henkel Foundation, and the American Research Institute of the South Causcasus.

Never miss a breakthrough: Join the SciTechDaily e-newsletter.

Follow us on Google, Discover, and News.

This web page was created programmatically, to learn the article in its unique location you possibly can go to the hyperlink bellow:

https://scitechdaily.com/how-copper-smelters-accidentally-sparked-the-birth-of-the-iron-age/

and if you wish to take away this text from our web site please contact us