This web page was created programmatically, to learn the article in its authentic location you possibly can go to the hyperlink bellow:

http://www.sciencedaily.com/releases/2025/10/251016223106.htm

and if you wish to take away this text from our website please contact us

Scientific breakthroughs not often occur unexpectedly. More usually, they evolve slowly, as researchers and engineers construct on years of regular progress till the extraordinary ultimately turns into routine.

Now, scientists could also be reaching a turning level in that gradual journey. Researchers from the University of Michigan and the Air Force Research Laboratory (AFRL) have demonstrated a solution to 3D print intricate tubular buildings whose distinctive inner geometry permits them to suppress vibrations in methods by no means seen in pure supplies. These creations belong to a category referred to as mechanical metamaterials — engineered substances with properties that come completely from their design quite than their composition.

The capability to dam or scale back vibrations could possibly be helpful throughout many industries, from transportation to building and past. The crew’s findings, revealed in Physical Review Applied, construct on many years of principle and laptop modeling to supply real-world buildings that may passively disrupt vibrations touring via them.

“That’s where the real novelty is. We have the realization: We can actually make these things,” stated James McInerney, a analysis affiliate on the AFRL. McInerney was beforehand a postdoctoral fellow at U-M working with Xiaoming Mao, a professor of physics, who can also be an writer of the brand new research.

“We’re optimistic these can be applied for good purposes. In this case, it’s vibration isolation,” McInerney stated.

The challenge obtained partial funding from the Defense Advanced Research Projects Agency (DARPA) and the Office of Naval Research, and likewise concerned help from the U.S. National Research Council Research Associateship Program, administered by the National Academies of Sciences, Engineering and Medicine.

Contributors included Serife Tol, an affiliate professor of mechanical engineering at U-M; Othman Oudghiri-Idrissi of the University of Texas; and Carson Willey and Abigail Juhl of AFRL.

“For centuries, humans have improved materials by altering their chemistry. Our work builds on the field of metamaterials, where it is geometry — rather than chemistry — that gives rise to unusual and useful properties,” Mao stated. “These geometric principles can apply from the nanoscale to the macroscale, giving us extraordinary robustness.”

Structural foundations

According to McInerney, the research brings collectively classical structural engineering, trendy physics, and cutting-edge manufacturing instruments reminiscent of 3D printing.

“There’s a real probability that we’re going to be able to manufacture materials from the ground up with crazy precision,” he stated. “The vision is that we’re going to be able to create very specifically architectured materials and the question we’re asking is, ‘What can we do with that? How can we create new materials that are different from what we’re used to using?'”

As Mao famous, the crew just isn’t altering a cloth’s chemistry or molecular make-up. Instead, they’re exploring how controlling form and construction at a wonderful scale can produce new and advantageous mechanical properties.

In nature, this strategy already exists. Human bones and plankton shells, as an example, use intricate geometries to realize outstanding power and resilience from easy supplies. With applied sciences like 3D printing, scientists can now replicate and improve that pure design precept in metals, polymers, and different substances to attain results that have been beforehand out of attain.

“The idea isn’t that we’re going to replace steel and plastics, but use them more effectively,” McInerney stated.

New-school meets old-school

While this work does depend on trendy improvements, it has necessary historic underpinnings. For one, there’s the work of the well-known nineteenth century physicist, James Clerk Maxwell. Although he is finest recognized for his work in electromagnetism and thermodynamics, he additionally dabbled in mechanics and developed helpful design issues for creating steady buildings with repeating subunits referred to as Maxwell lattices, McInerney stated.

Another key idea behind the brand new research emerged within the latter half of the twentieth century, as physicists discovered that attention-grabbing and perplexing behaviors emerged close to the sides and bounds of supplies. This led to a brand new discipline of research, referred to as topology, that is nonetheless very energetic and dealing to clarify these behaviors and to assist capitalize on them in the true world.

“About a decade ago, there was a seminal publication that found out that Maxwell lattices can exhibit a topological phase,” McInerney stated.

Over the final a number of years, McInerney and colleagues have explored the implications of that research as they pertain to vibration isolation. The crew has constructed up a mannequin explaining that habits and how one can design an actual object that may exhibit it. The crew has now proved that its mannequin is at its most superior stage but by truly making such objects with 3D printed nylon.

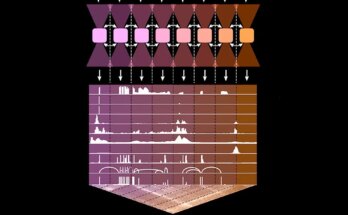

A cursory take a look at the buildings reveals why making them beforehand was such a problem. They resemble a chain-link fence that is been folded over and rolled up right into a tube with a linked internal and outer layer. Physicists name these kagome tubes, a reference to conventional Japanese basket weaving that used comparable patterns.

This is, nonetheless, simply step one in realizing the potential of such buildings, McInerney stated. For occasion, the research additionally confirmed that the higher a construction is at suppressing vibrations, the much less weight it may help. That is a expensive, probably even unacceptable, tradeoff by way of functions, however it highlights attention-grabbing alternatives and questions that stay at a elementary degree, he stated.

As such novel buildings are made, scientists and engineers are going to want to construct new requirements and approaches to check, characterize and assess them, which is a problem that excites McInerney.

“Because we have such new behaviors, we’re still uncovering not just the models, but the way that we would test them, the conclusions we would draw from the tests and how we would implement those conclusions into a design process,” he stated. “I think those are the questions that honestly need to be answered before we start answering questions about applications.”

This web page was created programmatically, to learn the article in its authentic location you possibly can go to the hyperlink bellow:

http://www.sciencedaily.com/releases/2025/10/251016223106.htm

and if you wish to take away this text from our website please contact us